When a customer comes to us looking to have lockers made for a school, office, or other facility, they come with a list of features they would like included in the final product. But when everything is tallied up on that perfect, high-quality locker, many times people find that they have exceeded their budget altogether.

What is a Value Engineered Product?

Value engineering comes in to reduce costs by cutting non-essential aspects of the locker in attempts to get down to the customer’s ideal price. What it’s supposed to do is find the balance between affordability without compromising on quality.

Sometimes, however, manufacturers take this too far. Making the price point the primary factor, rather than applying any quality standards to strive for. When value engineering is taken too far, the entire locker can be undermined, often without the customer even being fully aware of what they’ve agreed to in the name of savings.

That’s the slippery slope of value engineering that manufacturers can eventually go too far down, giving up features that are integral to the integrity of the locker as a whole.

Value Engineering Done Right

DeBourgh Lockers does their share of true value engineering products, even after other locker companies have come so far down on price and quality that we can no longer be competitive in that market. Still, we have remained true to the quality standards that we’ve always believed to be appropriate, simply because we aren’t willing to compromise on key standards.

When we realized that customers were accepting products that were far below any quality that we, ourselves, wouldn’t feel confident putting out, we started to look at how we might value engineer our lockers to offer more affordable options while still maintaining a high caliber of craftsmanship. Value engineering is not inherently a negative term and if it’s done properly it can be a great tool used to honor quality for customers who are willing to accept lesser products for less cost.

The Concerns

When customers recognize that their list of requests cannot be accommodated by their budget, we can work with them to find out what aspects are must-haves and which are not. We show what features could be removed without losing the lockers overall functionality.

The right way to do this would be to only remove aspects that are non-essential to a quality product. But what has happened in the locker market, is that when money is the only driving factor, and the initial need is no longer discussed, then value engineering becomes a simple chopping of price, regardless of the features that were initially important.

Perception is important. What DeBourgh strives to push back against is manufacturers that come up with supposed solutions that sound good, but incorporate major compromises in the integrity of their product. For instance, we have seen locker companies who compensate for using a thicker gauge of steel by leaving the back of the locker off altogether. Such major concessions in quality and security aren’t worth it in the end, especially if the customer isn’t fully aware of the implications of what they’re agreeing to in the product.

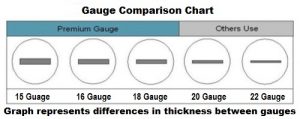

Heavier gauge locker does not mean that it is a better locker. So this brings up the question of what’s considered important and what’s expendable?

Features That Can be Flexible

There are certain features of a locker that are flexible, and these may be the first place to look into when considering a value engineered product:

●  Material Gauge: The thickness of the locker material is less important than the overall construction. It’s possible to make a locker with thinner material and have a quality product, so long as the construction is of a high caliber. If you’re looking into a lower gauge solution, ensure that you’re offered A fully welded locker.

Material Gauge: The thickness of the locker material is less important than the overall construction. It’s possible to make a locker with thinner material and have a quality product, so long as the construction is of a high caliber. If you’re looking into a lower gauge solution, ensure that you’re offered A fully welded locker.

● Door Thickness: You can also have a door be constructed of a thinner gauged material but if it doesn’t have at least two bends, then you’ll have seriously compromised door. A 16-gauge door could work, so long as there is a sufficient bends or a back panel to keep it secure.

● Door Strike: We prefer to have every side of the door reinforced on the other side, but it is acceptable to take a few of those side strikes out. This changes the rigidity and quality of the locker, but not to its detriment.

Essential Features That Cannot be Sacrificed

There are certain aspects of your locker that should never be compromised on, or you’ll see a serious decrease in the longevity and functionality of your product.

● Paint Thickness: Instead of providing a high-quality finish, too many value engineered products are only given a paint coating with 1 mil of thickness instead of the needed 2-3 mil. If a locker spec does not call out a powder coat or baked enamel thickness of 2-3 mils, a manufacturer can take advantage by applying paint at a thickness that’s far too thin to offer sufficient protection. This saves the manufacturer money and potentially the customer too but it undermines the integrity of the locker. Don’t compromise on paint!

● Construction: For a thinner locker gauge to work, customers should be willing to invest in a welded locker. The cost will be slightly more for the welded construction but is the only way to maintain integrity if you’re opting to choose a product with thinner material.

Find A Manufacturer You Can Trust

The whole point of true value engineering is to save on costs without undermining the locker itself. Success occurs when manufacturers can identify places to cut costs while staying firm on the features that make-up a high-quality locker. Manufacturers can’t be afraid to say when changes aren’t a good idea especially if that product won’t work well in certain environments or rough under  conditions.

conditions.

Customers take a lot of risk when the price is walked back and they are the ones ultimately responsible for the lesser quality product. There’s not a lot of protection for customers who accept value engineering, so make sure you ask lots of questions about any downsides to possible changes. Be aware of what you’re sacrificing when marking down the cost and decide if what you’re losing out on is worth the savings. Remember, you’ll have these lockers for years, maybe decades depending on the quality, and higher quality for higher cost may very well be worth it in the long run.

Find a locker manufacturer that is willing to tell you when it’s not a good idea to cut costs, and where you can truly afford to make changes. For customized assessments of your locker plans, contact DeBourgh Lockers.